Innovation

We consider technological innovation one of the most important strategic levers to continue playing a leading role in the country’s energy market, and to remain competitive also in the international context.

In addition, technological innovation is a crucial element to increase operational efficiency, reduce consumption, losses and disoptimisations, while increasing quality of the refined products. As such, Saras carries out industrial development activities aimed at achieving operational excellence and maximizing value creation, in the interests of all shareholders and in compliance with the highest safety standards for employees, the community and the region.

The industrial site managed by Sarlux in the Sarroch area is one of the most evolved at European level, with regards to integrated refining plants. It has technologically cutting-edge, flexible, versatile and high-conversion units. It has been integrated, since 2001, with an Integrated Gasification Combined Cycle (IGCC) plant that produces electricity and provides the refinery with large quantities of hydrogen and steam.

In line with the industial plan, further technological improvements have been identified to optimise the production cycles:

Maximisation of yields and conversion

with the implementation of technologies aimed at reducing technical constraints and limitationsFull exploitation of the petrochemical section

thanks to interventions aimed at increasing the recovery of specific components

Implementation of additional actions in the energy-saving field

improving the overall energy balance of the entire industrial siteInitiatives to minimise the use of local water resources

optimising the entire water network

Saras is a pioneer in the

digitalisation of processes and

the transition to the 4.0

industry with the aim of

boosting reliability and efficiency.

#DigitalSaras

At end of 2016, the #digitalSaras program was born and a dedicated team was set up with the aim of developing all the potentials.

To remain one of the leading refining operators and to improve processes at sustainable costs, making them more fluid but at the same time more effective, the big data management challenge has been seized: analyzing and exploiting these data is essential to play in advance and support the whole decision-making process represents a tangible and tangible step towards an evolution that is not only technological but also of mentality.

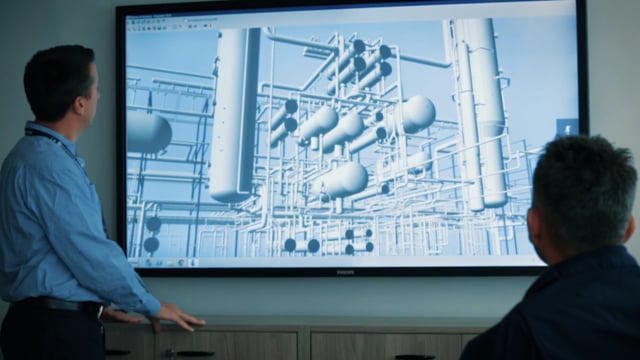

Some examples of projects carried out concern the use of industrial robots able to cooperate with humans, the 3D reproduction of equipment to have a more and more reliable and effective control of the quipment, the use of explosion-proof tablets for the verification work of the plant operators, the exploitation of a communication platform that allows to store in a structured way all the information that is collected in the various turnovers and the creation of algorithms that provide information on the processing cycle of the gasifiers useful for strategic planning management.

COMPLETE

Focus on more than 100 possible digital initiatives

COMPLETE

Identification of 10 pilot projects

ONGOING

Industrialisation of pilot projects